What Types of Custom Electrical Enclosures Can XYD Manufacture?

Custom Electrical Enclosures

XYD is a professional manufacturer of custom electrical enclosures in China, providing tailor-made enclosure solutions for both indoor and outdoor applications.

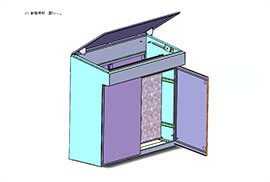

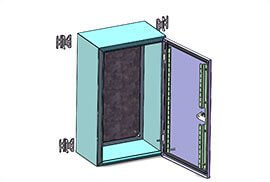

We design and manufacture custom enclosures in virtually any size, structure, and configuration, with precision cutouts to ensure perfect component fit.

All XYD custom electrical enclosures are engineered to meet international standards, including UL, IEC, and Ingress Protection (IP) requirements.

Whether for industrial control, automation, telecom, or power distribution, XYD delivers enclosures built for performance, safety, and durability.

Key Elements to Consider in Custom Electrical Enclosure Design

A well-designed custom enclosure improves functionality, protection, and overall product value.

At XYD, we carefully evaluate every design detail, including:

-

Enclosure size and dimensions

-

Gland plates and cable entries

-

Mounting type (wall-mounted, floor-standing, pole-mounted, etc.)

-

Color and surface finish

-

Custom cutouts and openings

-

Viewing windows

-

Door structure and opening direction

-

Mounting plates and internal panels

-

Sheet metal thickness

-

Door locks and security systems

-

Protective covers or shielding

-

Special packaging requirements

-

Optional accessories: insulation, fans, filters, lighting, and more

How XYD Manufactures Custom Electrical Enclosures

1. Project & Application Review

Our engineers first evaluate your application requirements, installation environment, and industry standards to recommend the most suitable enclosure solution.

2. Selecting the Right IP Rating

Indoor and outdoor installations require different protection levels. XYD ensures your enclosure meets the correct IP rating for dust, water, and environmental exposure.

3. Enclosure Configuration Confirmation

We confirm all internal layout details, including mounting plates, racks, panels, and component spacing, to ensure easy installation and maintenance.

4. Custom Enclosure Design

After confirming technical details, XYD creates detailed CAD / SolidWorks drawings for your review and approval before production begins.

5. Material Selection

Based on your application, we recommend the most suitable enclosure material, balancing strength, corrosion resistance, cost, and performance.

6. Dimension Verification

Precise height, width, and depth ensure a space-saving, easy-to-install, and cost-effective custom enclosure.

7. Powder Coating & Surface Finishing

We offer professional powder coating and finishing options to enhance durability, corrosion resistance, and brand identity.

Available Materials for XYD Custom Electrical Enclosures

XYD manufactures enclosures using high-quality metals, strictly following NEMA and international standards.

Stainless Steel

Stainless steel offers excellent strength, corrosion resistance, and chemical resistance.

Common grades include 304 and 316, suitable for harsh, humid, or chemical environments.

Carbon Steel

Available in hot-rolled and cold-rolled options.

Hot-rolled steel is ideal for moderate forming, while cold-rolled steel provides better surface quality and dimensional accuracy.

Aluminum

Lightweight and cost-effective, aluminum provides strong corrosion resistance and good mechanical strength.

It is also effective for EMI shielding and performs well in demanding environments.

All XYD metal enclosures ensure proper electrical grounding, bonding, and electromagnetic interference protection, safeguarding internal equipment.