XYD – Professional Sheet Metal Fabrication Factory in China

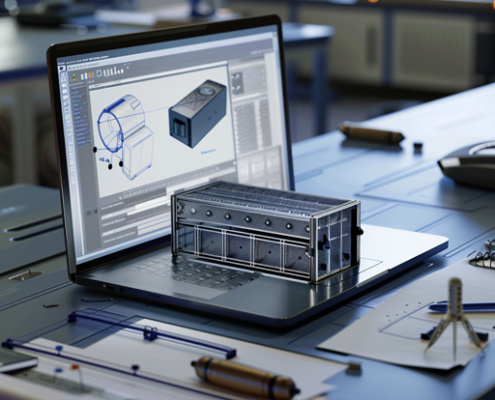

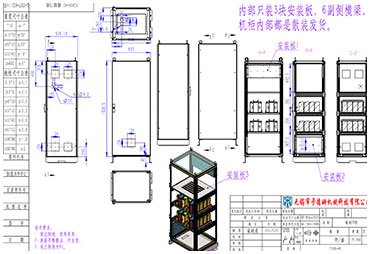

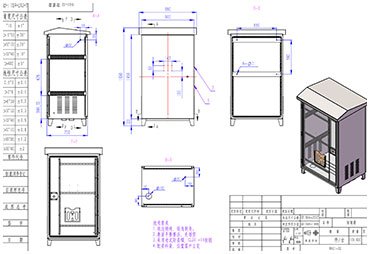

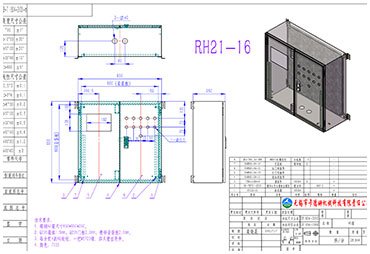

XYD provides professional sheet metal fabrication services for a wide range of products, structures, and components. We support multiple fabrication processes, including laser cutting, bending, welding, stamping, and assembly, allowing us to deliver precise and reliable custom metal parts.

Our engineering team works closely with customers to process different sheet metal materials and form them into complex shapes based on specific design and application requirements. From simple components to fully customized enclosures, we ensure accuracy at every stage.

XYD is equipped with advanced fabrication machinery and dedicated tooling to support stable and efficient production. Our workshop includes high-precision cutting equipment and modern press brakes, enabling clean cuts, tight tolerances, and consistent bending results.

Our sheet metal fabrication solutions are widely used across various industries, such as electrical, industrial equipment, construction, and transportation, where durability and precision are critical.

If you are looking for a reliable partner for custom sheet metal fabrication, XYD is ready to support your project from design to delivery.