Electrical Enclosure Bending

The increasing demand for custom-made electrical enclosures has made it possible for different sheet metals to be transformed into numerous configurations.

Metal sheet bending is one of these techniques used for making different electrical enclosure designs.

Technically, electrical enclosure bending is a process of deforming a particular metal by applying force to it.

The metal sheet consequently bends at a particular angle to form the desired shape.

KDM Steel offers a wide range of electrical enclosure bending solutions to form different sizes and shapes.

We use different tools, equipment, and process, which guarantee simplicity and efficiency.

The essence is usually to alter the external features of the sheet but retain its parameters such as length and thickness.

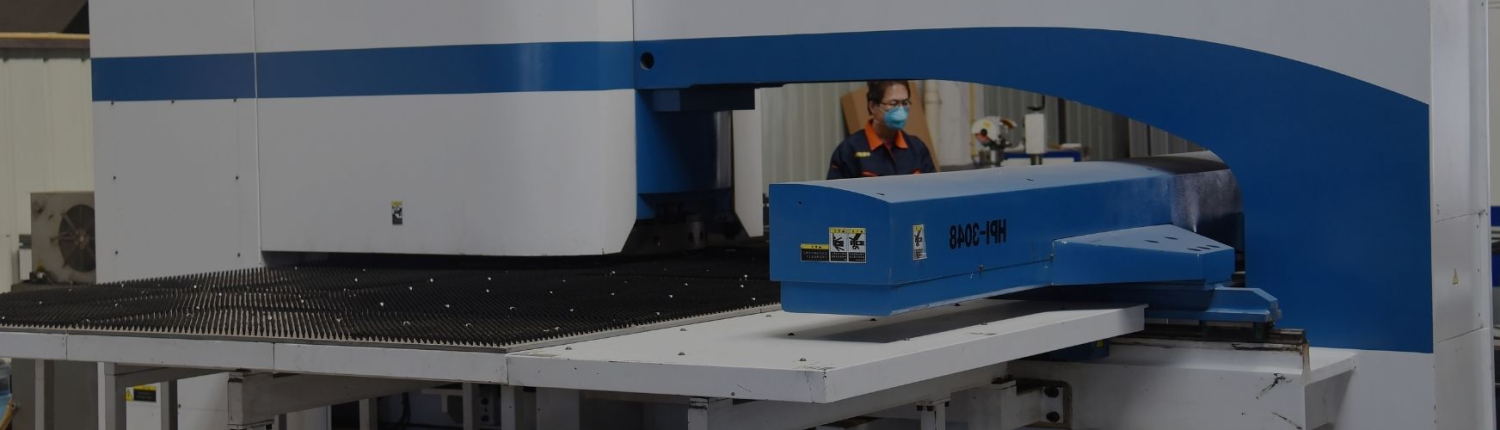

Types Of Press Brakes Used In Electrical Enclosure Bending

At XYD Steel, we offer many press brakes to ensure you get the best results possible in electrical enclosure bending.

The common types we often use include the following;

Pneumatic

It entails use of a compressor when supplying airpower to bend a sheet of electrical enclosure metal.

Ordinarily, we use this press brake for electrical enclosures, which require less pressure. It is also an ideal option when handling relatively small-sized electrical enclosures.

Mechanical

It features a design, which makes it suitable for air bending. The primary benefit of this choice is that it offers accuracy and speed.

Hydraulic

This type of press brake uses advanced technology guaranteeing precise bending on the electrical enclosure. It gives you proper material bending and yields better accurate results.

CNC Press Brakes

It is the use of highly advanced technology to bend electrical enclosures into different configurations.

This option utilizes computerized software, which is vital since it guarantees accuracy, speed, safety, and efficiency.

Methods Of Electrical Enclosure Bending

Cost Of Electrical Enclosure Laser Cutting At XYD Steel

Ideally, the processes for electrical enclosure bending are relatively similar.

The end goal is usually to transform the particular sheet metal’s structures to the desired forms. Nevertheless, the bending processes tend to vary in operation.

At KDM Steel, we understand that bending any electrical enclosure requires knowledge of many factors such as material thickness, size of bend, and intended enclosure design.

Some of the core methods we usually use to bend different electrical enclosures include the following;

V- Bending

It is among the commonly used bending technique that KDM Steel uses for various electrical enclosure bending projects. This process involves using a punch and v-die to bend the sheet metal into desired angles. The angle formed by electrical enclosure sheet metal depends on the pressure point of the punch. As such, it makes the process easy and efficient

V-Bending is classified into three categories, which include the following;

- Bottoming

- Coining

- Air bending

Roll Bending

This is another technique KDM Steel uses to bend sheet metals into electrical enclosures.

It involves a hydraulic press, press brake, and sets of rollers to make different bends or a large bend electrical enclosure.

Roll bending is ideal for making hollow-shaped electrical enclosures since it capitalizes on distance between rollers to form bends and curves.

U-Bending

Principally, u-bending is akin to v-bending since they use similar instruments, albeit with a different configuration.

U-Bending uses a U-die, thus the formation of u-shaped electrical enclosures and related components.

Wipe Bending

KDM Steel also uses wipe bending to form the edges of electrical enclosures.

The actual process is, however, dependent on wipe die since the sheet metal must be pushed into the wipe die appropriately.

The wipe dies also determines the inner radius of sheet metal bend.

Rotary Bending

This electrical enclosure bending method is more advantageous than v-bending or wipes bending since it hardly scratches the surface material of this component.

It is also suitable since it can bend materials into sharp corners.

Main Factors To Consider In Electrical Enclosure Bending

XYD Steel has immeasurable experience in handling different electrical enclosure bending projects.

Over time, we have handled thousands of electrical boxes bending projects for both standard and custom designs.

Some bending processes are usually complex and thus require experience, knowledge, and right equipment to attain best results.

Here are some of the essential elements XYD Steel usually looks into when bending different electrical enclosure designs;